This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Version 3.2

The Most Comprehensive Solutions for Industrial CT Data Just Got Even Better

Version 3.2 Is Here

In version 3.2 of our software, users benefit from new options for tool and geometry corrections, quicker analysis of repetitive structures, a completely reworked automation tool, and a more meaningful assessment of mechanical effects of porosity to name just a few of the new features. Especially for globally active companies we’re introducing a new Global Floating license.

Correction of Casting or Molding Tools as well as 3D Printing Geometries

From Tool Correction to 3D Printing Geometries

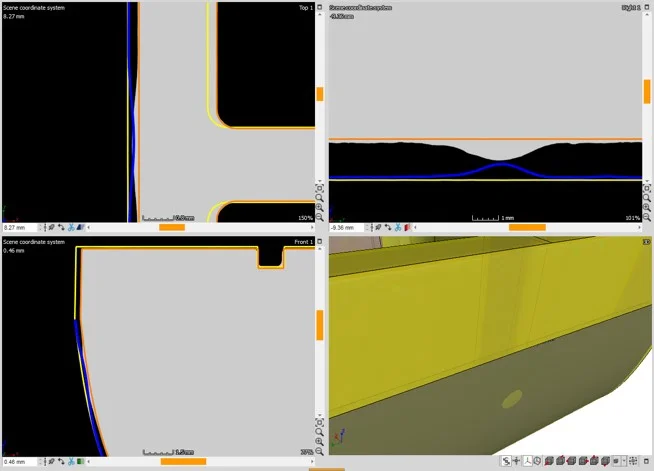

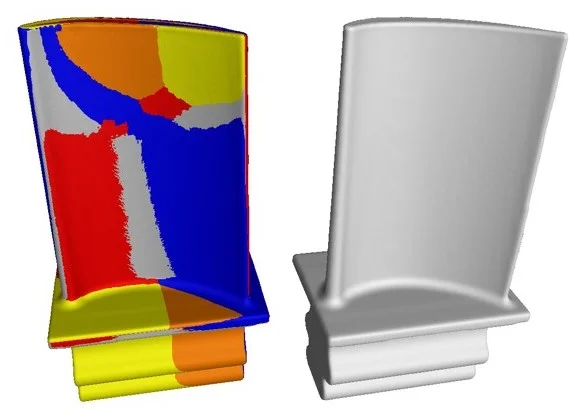

The new Manufacturing Geometry Correction Module for VGSTUDIO MAX (Coordinate Measurement and Nominal/Actual Comparison Module required), VGMETROLOGY, and VGMETROLOGY ES, combines the manufacturing, testing, and correction of tools and components into a seamless digital workflow. It is a cost effective, easy to use, and versatile method for tool correction, surface reconstruction of a manually reconstructed tool, and part correction of 3D printing geometries.

The new Manufacturing Geometry Correction Module is available for VGSTUDIO MAX, VGMETROLOGY, and VGMETROLOGY ES

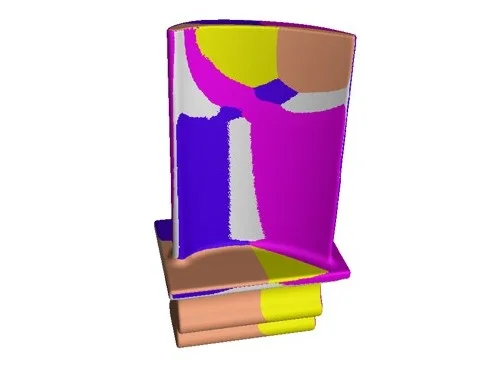

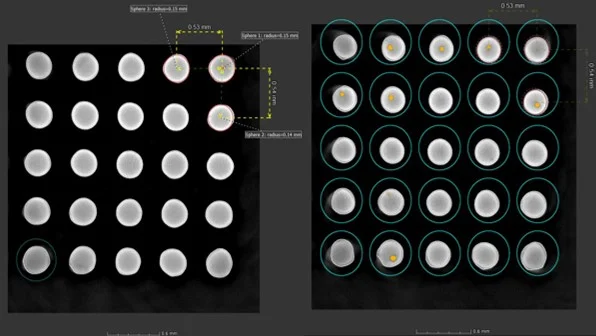

The golden surface function lets you create an average surface of the parts

Correcting Injection Molding Nests

In VGSTUDIO MAX and VGMETROLOGY, you can use the Manufacturing Geometry Correction Module in combination with our new “golden” surface function to correct an injection molding tool with multiple identical nests. The golden surface function lets you create an average surface of the parts coming from the different nests which is the best basis for correcting the geometry of the nests – whereas variances between the nests are more likely an outcome of inhomogeneous process parameters.

CT Based Metrology

Define a Measurement Plan Even If No CAD Model Is Available

The average surface – created with the new golden surface feature in VGSTUDIO MAX or VGMETROLOGY – can also be used as a basis for the definition of a measurement plan if no CAD model is available. This lowers number of errors when applying the measurement plan to multiple scans, especially in automated inspection.

Multiple Registrations on One Object

Switch between different registrations of an object to see which out of several possible registrations minimizes the deviations to a reference object. In VGSTUDIO MAX, VGMETROLOGY, and VGMETROLOGY ES, you can now store multiple registrations on one object and easily switch between them; measurements are updating accordingly.

The new golden surface feature lowers the number of errors when applying the measurement plan to multiple scans

Sequential alignment is a new intuitive method to register two objects against each other

Align Two Objects Intuitively

Sequential alignment is a completely new method to register two objects against each other based on corresponding pairs of geometry elements, without first having to register each object to a coordinate system. This intuitive step-by-step process is similar to what you would do with physical objects. The result of each alignment step is immediately visible. If not all degrees of freedom are important, the alignment can remain incomplete. Or set the remaining degrees of freedom by using the best fit method. Sequential alignment is available in VGSTUDIO MAX, VGMETROLOGY, and VGMETROLOGY ES.

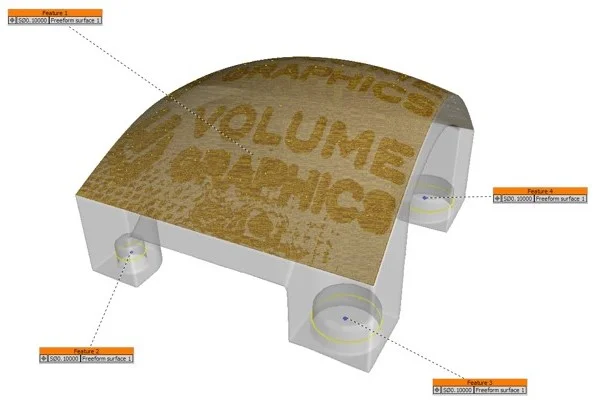

Use Organic Shapes as a Datum

With the support of complex datums, we’ve added the option to use freeform surfaces and combination of surfaces as datum objects for registration and geometric tolerancing. This is useful in cases where organic shapes, e.g., a car dashboard or cavities of connectors, should be used as a datum.

Complex datums allow you to use organic shapes as a datum

Tolerance states of dimensioning features are now shown in all views by evaluation indicators

Recognize the Tolerance Status Immediately

You can now see at a glance if a dimension is within tolerance in all views – without looking at the scene tree or numerical values. In VGSTUDIO MAX, VGMETROLOGY, and VGMETROLOGY ES, the tolerance state of dimensioning features is now optionally shown in all views by evaluation indicators.

Generate “Watertight” .stl Meshes

A new “grid-based” algorithm in VGSTUDIO MAX, VGMETROLOGY, and VGMETROLOGY ES extracts surface meshes not only much faster. They are now also “watertight“, meaning that the meshes fully enclose a volume with no gaps and holes. This makes them perfect for most types of 3D printing.

What’s more, you can now also export .stl meshes from VGMETROLOGY and VGMETROLOGY ES.

Automated CT Inspection

Improved Automation

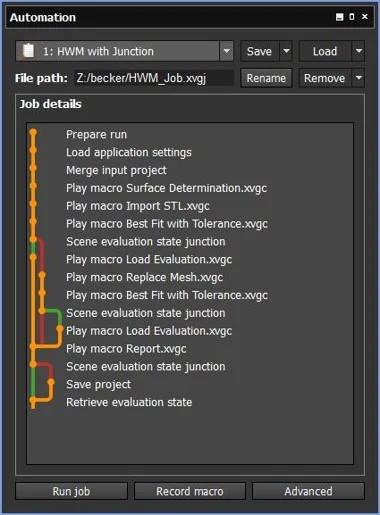

VGSTUDIO MAX 3.2, VGMETROLOGY 3.2, and VGMETROLOGY ES 3.2 come with a completely reworked and extended automation tool. It now supports the so-called “jobs” known from VGinLINE. Drawing from the full scope of available analyses, jobs combine macros, template, and all referenced data into one automation workflow.

If-then statements in jobs allow for even more complex automated inspections. For example, you can determine that further analyses are skipped if the part is already out of tolerance.

Also, input and output paths of macros can now be edited, saving you the time to re-record a macro.

Prepare and Test VGinLINE Jobs in VGSTUDIO MAX

By bringing jobs to VGSTUDIO MAX, the software becomes your central automation editor. It now offers a seamless workflow of editing and testing macros, evaluation templates, and VGinLINE jobs, which can then be transferred to VGinLINE for use in automated at-line or in-line inspection.

Traceability and Reporting

Compared to macros and templates alone, jobs can reflect incremental changes to a part by using revisions. With their unique IDs for revisions, jobs provide the necessary traceability. Furthermore, meta data information about the inspected component, e.g., from barcode scanners, can now be automatically imported.

If-then statements in jobs allow for even more complex automated inspections – now not only in VGinLINE but also in VGSTUDIO MAX

VGinLINE APPROVER now shows the position of defects or features in a 3D rendering

3D Defect Location in VGinLINE APPROVER

VGinLINE APPROVER becomes even more the easily accessible dashboard to review and manually re-evaluate results of an automated inspection. In addition to the 2D view, the web-based interface now shows the operator the position of detected defects or measured features in a 3D rendering of the component.

To share your inspection results, VGinLINE APPROVER can now export .pdf files which include the results of both the automated inspection and the manual revision.

Defect Assessment

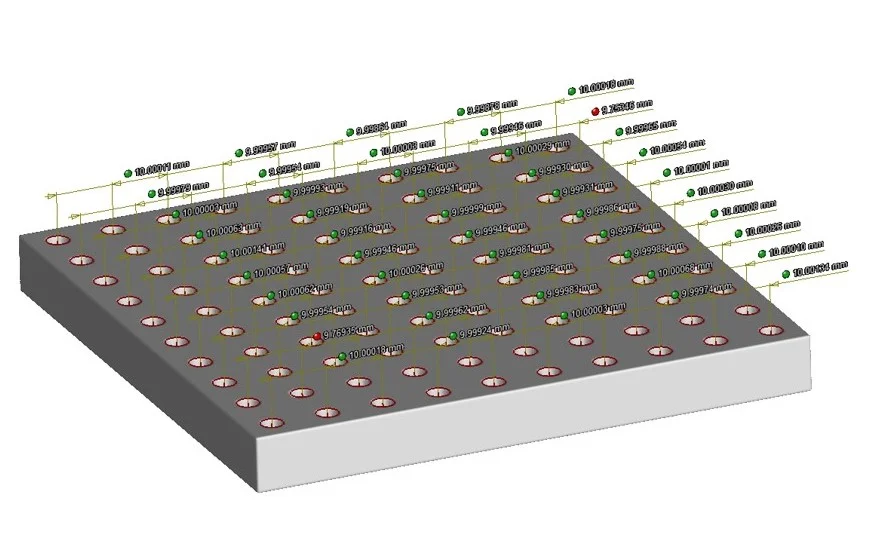

Quickly Assess Defects or Geometric Deviations across Multiple Regions

Version 3.2 makes analyzing repetitive structures such as cylinder heads or Ball Grid Arrays a breeze. You can now quickly copy one region of interest (ROI) multiple times into a periodic pattern; all analyses within this ROI, e.g., a defect analysis or a nominal-actual comparison, will be copied automatically.

You can now quickly copy one region of interest (ROI) multiple times into a periodic pattern

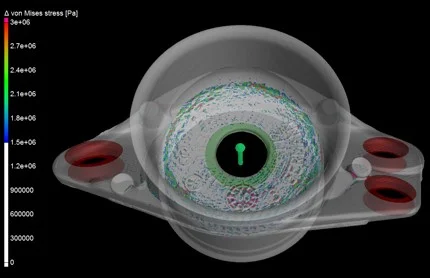

You can now compare the stress simulated on your scanned part with an equivalent stress simulated on the nominal part

Assess Mechanical Effects of Porosity

How does the porosity in a cast metal part influence its mechanical integrity? With just one click, you can now take the results of a porosity analysis into account in a structural mechanics simulation. In this way, VGSTUDIO MAX 3.2 not only finds defects but also calculates their mechanical effect.

In order to assess whether the defects significantly change the mechanical properties, you can now directly and numerically compare the stress simulated on your scanned part (with defects) with an equivalent stress simulated on the nominal part, represented by a CAD or an .stl model. The software then clearly shows you where and what the differences between your scanned part and the reference part are – leading to the most direct and meaningful characterization of the mechanical effects of the defects.

Materials Research and Development

Simulations with Variable Material Parameters

Perform micromechanical simulations of the effective elastic properties of compound materials, rocks, or bones. The Structural Mechanics Simulation Module now supports variable material parameters depending on gray values. Since no volume meshing is required, you avoid the high effort and potential inaccuracies associated with volume meshing.

Support of FIB/SEM Data

Analyze material probes such as rocks or battery materials in 3D with very high resolution in the nanometer range. With a new import filter for FIB-SEM data, you can now use the broad range of material structure analyses in VGSTUDIO MAX 3.2 on data from FIB-SEM microscopes.

More Flexible Display of Results of Material Structure Analyses

You can now define arbitrary directions, e.g., for fiber composite material analyses, foam structure analyses, and structural mechanics simulations.

Also, you can now define separate color look up tables for each instance of an analysis.

VGSTUDIO MAX 3.2 comes with a new import filter for FIB-SEM data

Global Floating License: Use Software Flexibly Worldwide

If you are a global company, you can now use one license in different locations in different time zones throughout the world. With this new Global Floating license type, you require fewer licenses compared to other license models.

Each of these Global Floating licenses can contain a different add-on module configuration. A user can start multiple instances of the software on the same computer without each one counting as a separate license. And soon, you’ll be able to “borrow” a license from your Global Floating license pool for a limited time, e.g., for a business trip or a conference.

Global Floating is an additional license model to the existing floating license. It’s available for VGSTUDIO MAX packages and packages with additional add-on modules, VGMETROLOGY, and VGMETROLOGY ES (both with or without add-on modules).

Get It Now

With a valid update/service agreement, you can upgrade your license for free. Download the latest version of VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, VGinLINE, or myVGL free of charge from your Download Account.

Contact Us

Contact Us

You don't have a valid update/service agreement? You are curious about the new Global Floating license? Just send our sales colleagues an e-mail or give them a call. They'll give you more information and assist you in purchasing or evaluating the new version:

For customers in Europe, Australia, South America, Africa:

sales@volumegraphics.com

+49 6221 73920-80

For customers in the US, Canada, and Mexico:

sales-us@volumegraphics.com

+1 704 248 7736

For customers in Asia (except China and Japan):

sales@volumegraphics.sg

+86 10 8532 6305

For customers in China, including Mainland China, Hongkong, Macao, and Taiwan:

sales@volumegraphics.cn

+86 10 8532 6305

For customers in Japan:

sales@volumegraphics.jp

+81 52 508 9682