This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

What's New in VGinLINE

Discover the Exciting New Capabilities of Version 3.4 (as of February 2021, Version 3.4.5)

Watch Our Free What's New Webinars

You missed our exciting What's New webinars on automation with VGinLINE 3.4 and VGSTUDIO MAX 3.4? No problem! Just click on one of the links below to watch the recording of the respective topic:

New Integrated Reporting (New in 3.4.4)

Completely new integrated reporting now lets you edit and view reports in Volume Graphics applications exactly as they will appear in the PDF, customize them, automate their creation, and store them directly in your .vgl project. The new integrated reporting function is a fast way to create presentable .pdf reports without having to switch to external software like Microsoft Excel and is available throughout our products, even in our free viewer applications myVGL and VGMETROLOGY VIEWER. And because report creation and export are macro-recordable, the new reporting is also available for automation and VGinLINE.

WYSIWYG Report Editor (New in 3.4.4)

The new WYSIWYG (What You See Is What You Get) editor as part of the completely new integrated reporting function makes it easy to create a more digestible view of your project data. You can create reports that contain all or a subset of the reportable content in the scene and customize the displayable content, such as images, table columns, or page layouts. Additionally, data sections in the report, like selected metainformation, volume information, analysis settings, or result images, can be reordered or removed altogether. Once a custom layout has been created, it can be stored and reused when similar content is to be reported.

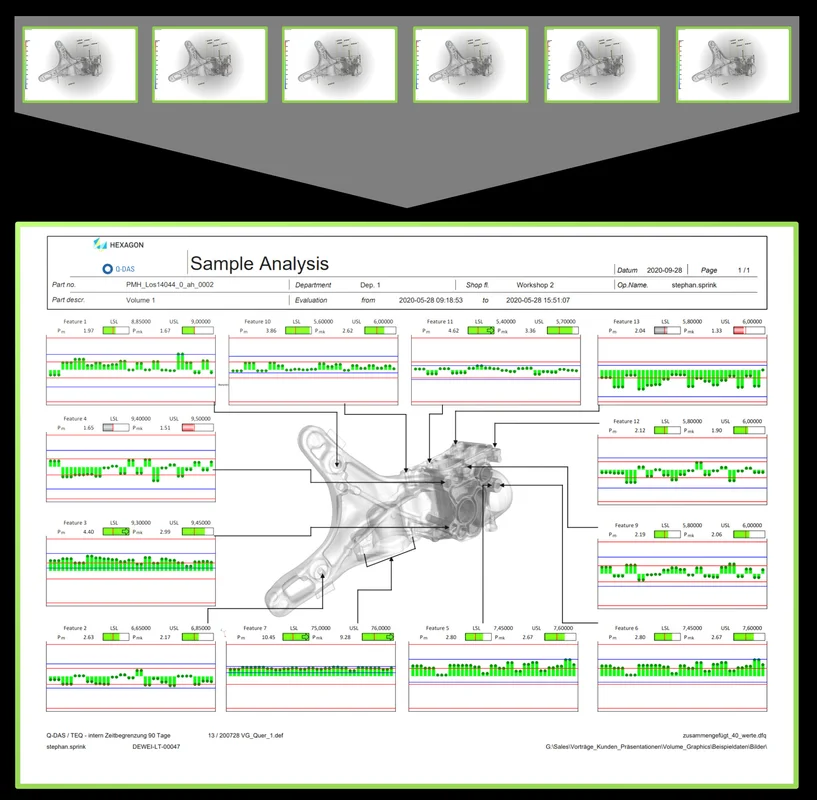

Image Support for Q-DAS Export (New in 3.4.3)

Exporting measurement results to Q-DAS software qs-STAT for statistical process control now includes associated images that indicate the position of the measured features on the part. These images can then be used to set up a report view in qs-STAT, which will be populated with the results of many measured parts. Visualizing measurement time series and the position of the measured features on the part make it easier to evaluate results, for example to locate a potential need for an injection molding tool correction during machine qualification or while production is running.

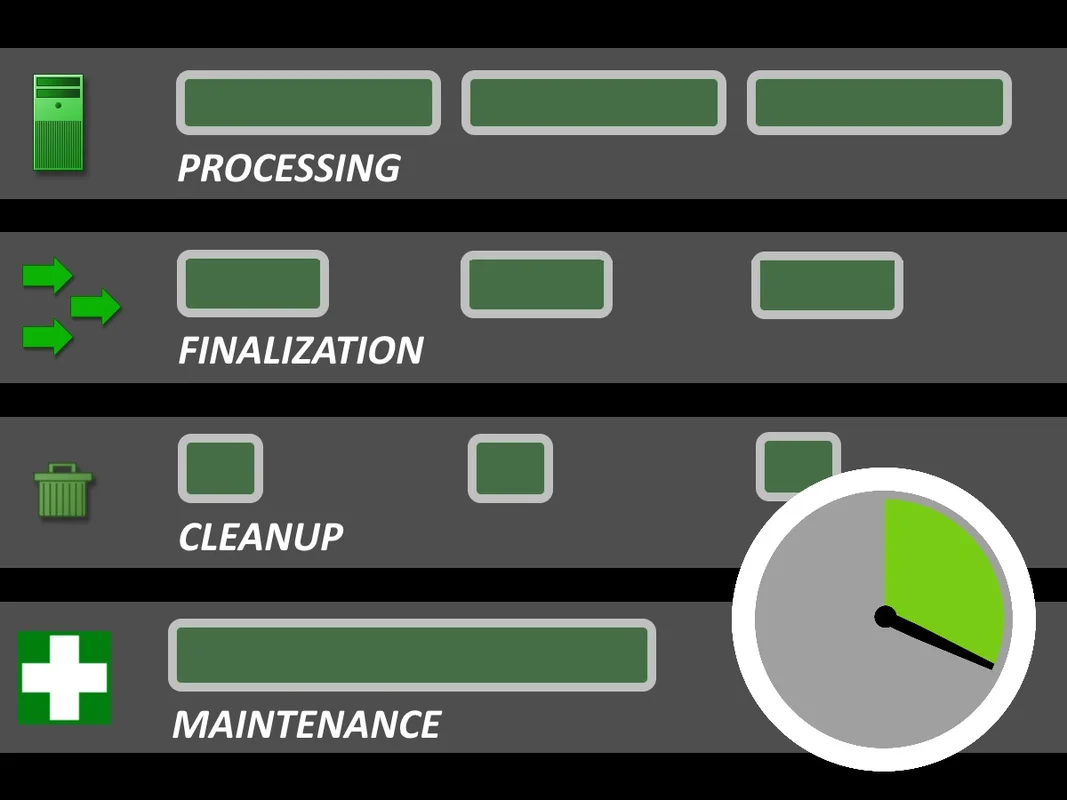

Parallel Task Processing by VGinLINE WORKER

The new parallel task processing by VGinLINE WORKER can handle auxiliary tasks, such as input or output file copying, while the inspection is running. This significantly speeds up throughput (depending on the size of files being copied), removes downtime because of long-running but non-CPU-intensive operations, and makes system behavior more predictable.

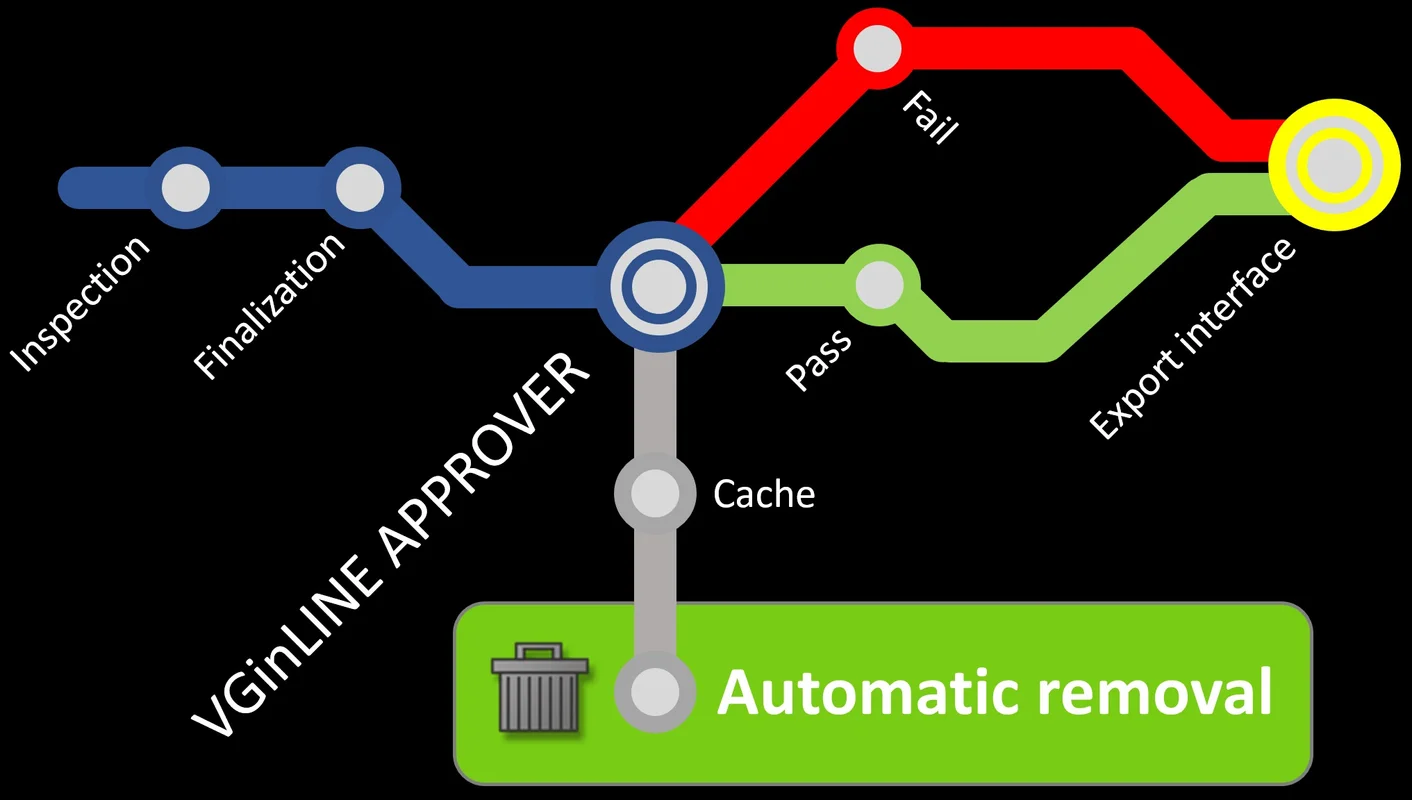

Automatic Result Removal in VGinLINE APPROVER

Automatic Result Removal in VGinLINE APPROVER

By automatically removing reviewed reports from the VGinLINE APPROVER database after a set amount of time, you can now accurately predict the required file system storage for a manual review system and limit the amount of reports available in the user interface, thus making navigation easier for the operator.

VGinLINE Jobs

- Prepared scene caching in VGinLINE automatically stores and reuses complex prepared scenes during job execution in a local cache, saving you time, for example, if the system was restarted or when different parts are inspected intermittently. (New in 3.4.5)

- Configurable text overlays in VGinLINE jobs: You can now let VGinLINE generate images that show an arbitrary configuration of text overlays during an automated inspection, making it more customizable to highlight relevant information like serial numbers or other metainformation fields.

File I/O

- Improved support for new NSI file format (.nsihdr): If the necessary converter application is missing, you will now get an informative error message. Also, the "Pack and go" function now works as expected with the new format. (New in 3.4.3)

Volume Graphics GmbH

Speyerer Straße 4-6

69115 Heidelberg

Germany

Phone: +49 6221 73920 60

Fax: +49 6221 73920 88

Sales enquiries:

sales@volumegraphics.com

Modifications and errors reserved.