This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

What's New in 2023.3

Highlights and Changelog

Version 2023.3 of VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, VGinLINE, and myVGL is now available for download. Benefit from the following innovative features.

Depending on the operating system, there will be differences in the range of functions. See our continuously updated Product Information page for details.

Feature Highlights

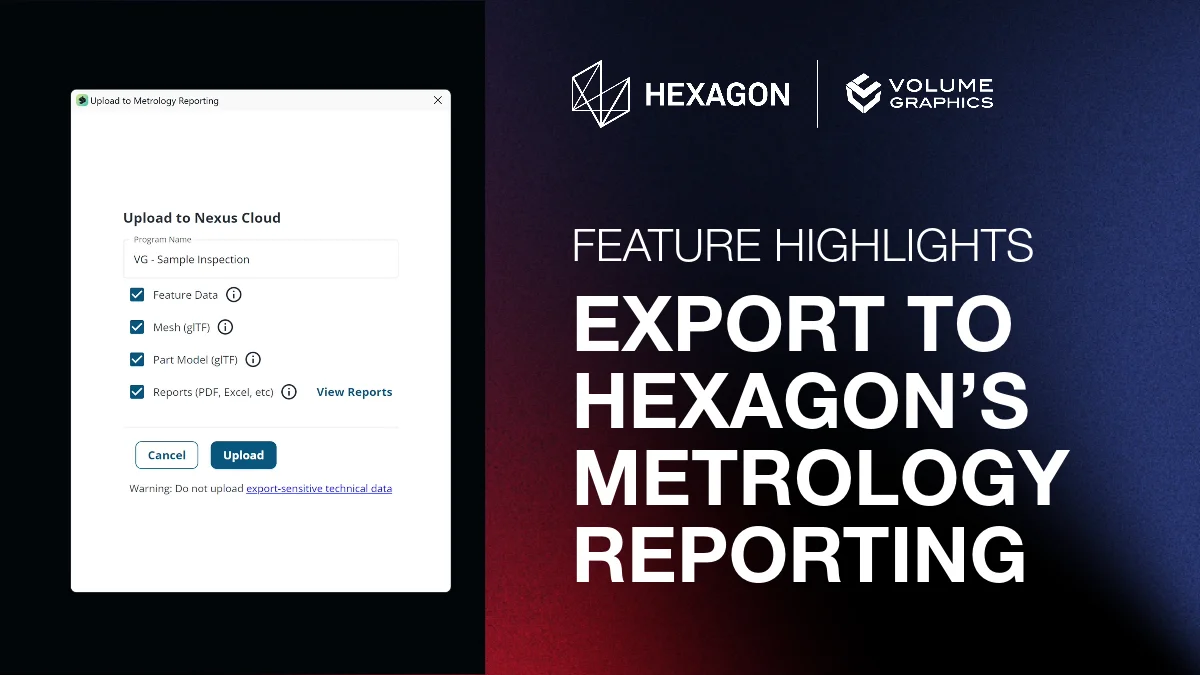

Export to Hexagon’s Metrology Reporting

You can now share inspection results, part information, and PDF reports from our software directly to the Metrology Reporting platform with the click of a button.

With Metrology Reporting, data-driven decision making has never been easier:

- Consolidate disparate reporting tools into one central location.

- Track the real-time status of measured parts, get failure details, and view metrology reports on any device at any time.

- Use centralized data to automate workflows

and reduce labor costs.

Learn more about this simple, intelligent, and accessible cloud‑based reporting and visualization tool here.

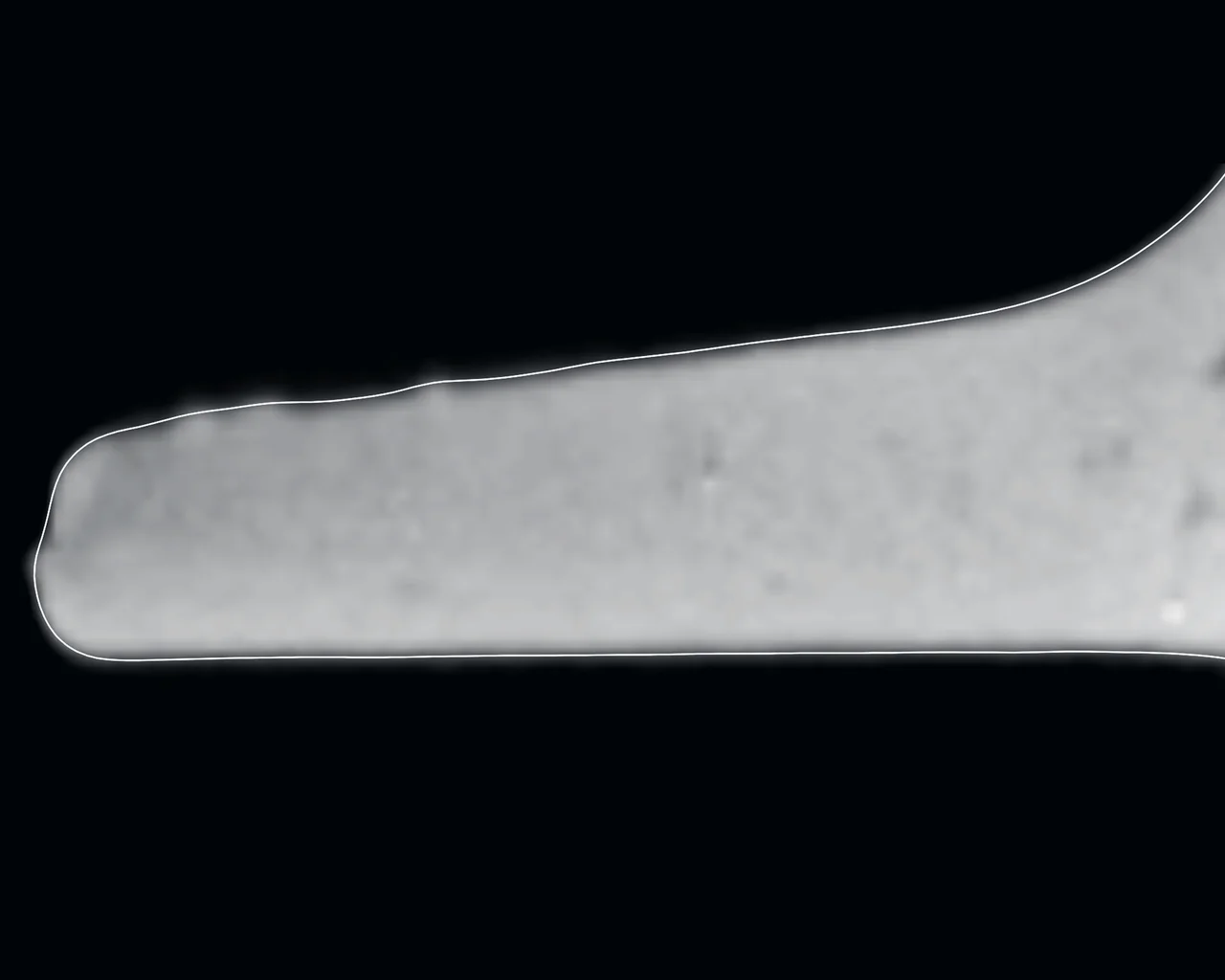

New Options for Handling Particles and Voids in the Advanced Surface Determination

You can now configure up to what size particles and voids should be filtered out of the advanced classic and multi-material surface determination.

The calculation is now done based on the result surface instead of the starting contour to avoid particles and voids being found again during the advanced surface determination within the search distance.

There is a new option for the advanced classic surface determination to create a two-component volume where the voids are separated from the material. This way, you can use the component selection to specify whether or not the surface of voids is to be considered in subsequent analyses (e.g., wall thickness analysis or nominal/actual comparison).

Enhanced Visualization of Tolerance Zones

The improved visualization as a volumetric zone makes it even easier to understand the programmed tolerance on the nominal part, as well as the tolerance state of the real object.

The tolerance zones are color-coded in green (OK) or red (not OK) depending on their evaluation state.

Geometric tolerances will now show their tolerance zones when selected in the Scene Tree and when automatic images are reported.

More Exciting New Features

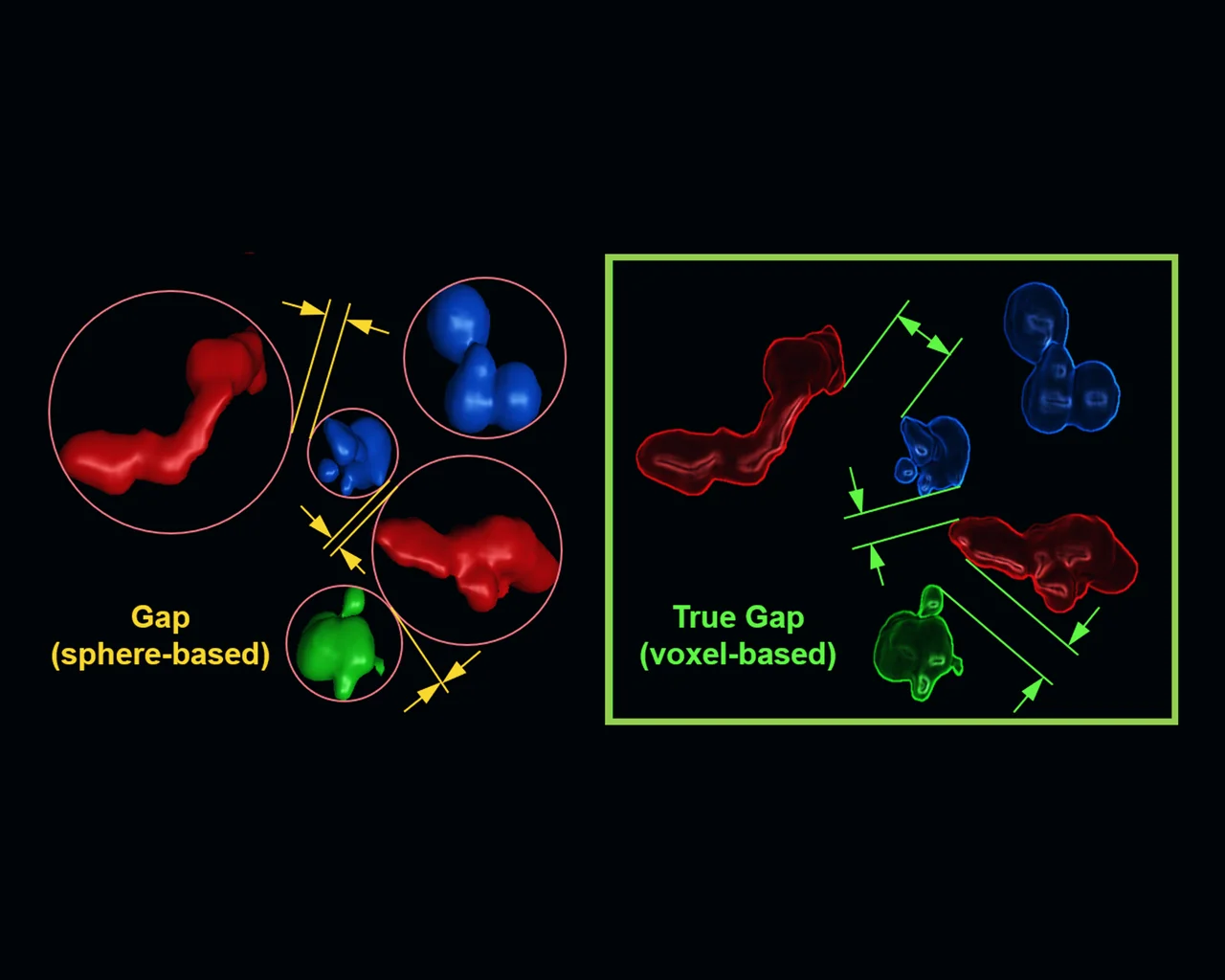

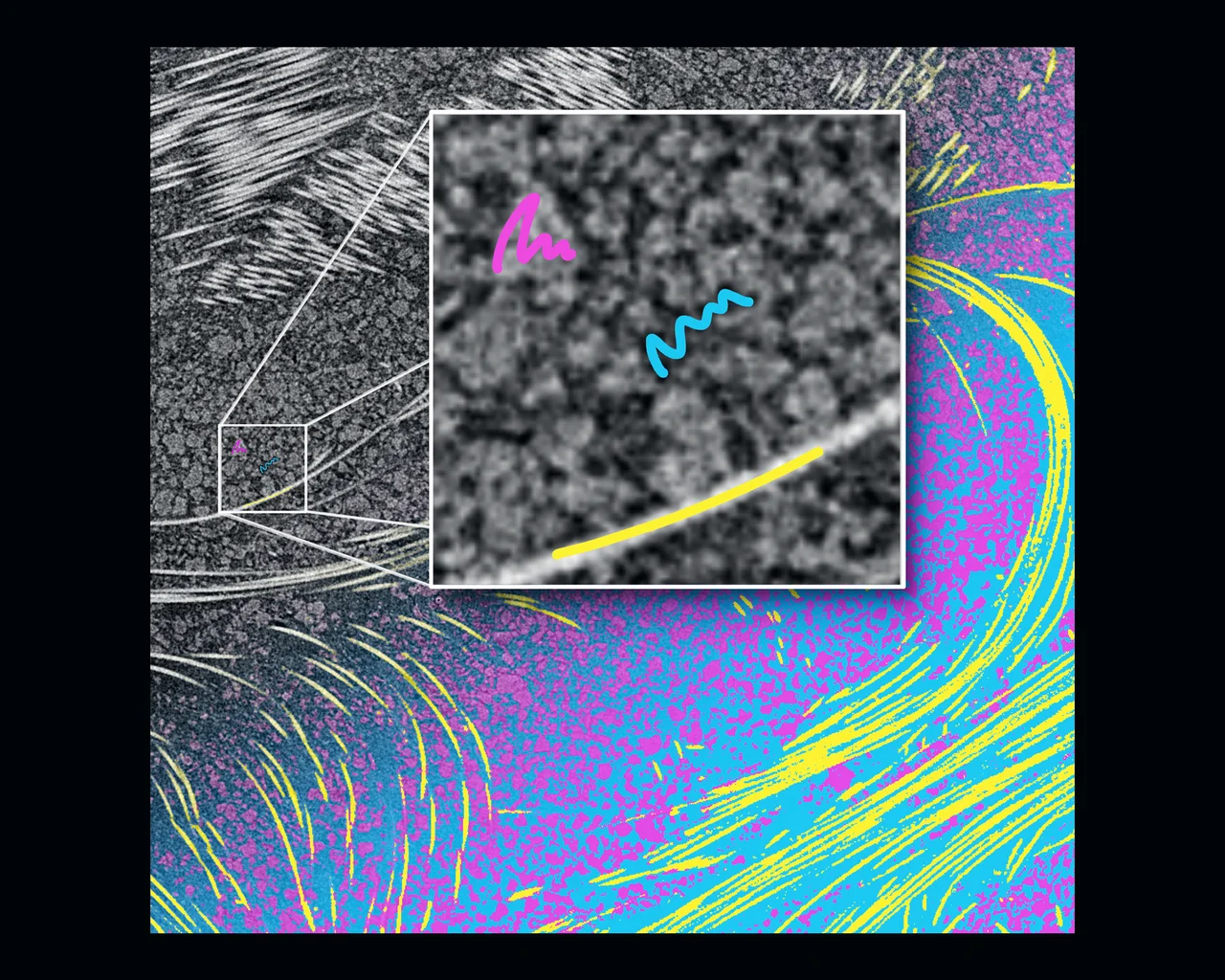

The New Go-To Standard for Porosity/Inclusion Analysis: Exact Calculation of the True Gap between Pores

Use our new voxel-based gap calculation to measure precise distances between pore surfaces and accurately determine the smallest gap for subsequent evaluation. This is an important addition to the software’s well-known gap calculation based on circumscribed sphere measurement.

This new feature allows for easier reporting and opens up entirely new possibilities in the porosity/inclusion analysis of CT scans:

- Measure the distance between hundreds of pores faster and more precisely than possible with conventional means like microscopy on metallographic specimen.

- Decrease the potential for false rejects.

The new voxel-based gap is now the default calculation for the porosity/inclusion analysis. Customers who wish to continue using the sphere-based gap calculation may do so by changing the selection before conducting their analysis.

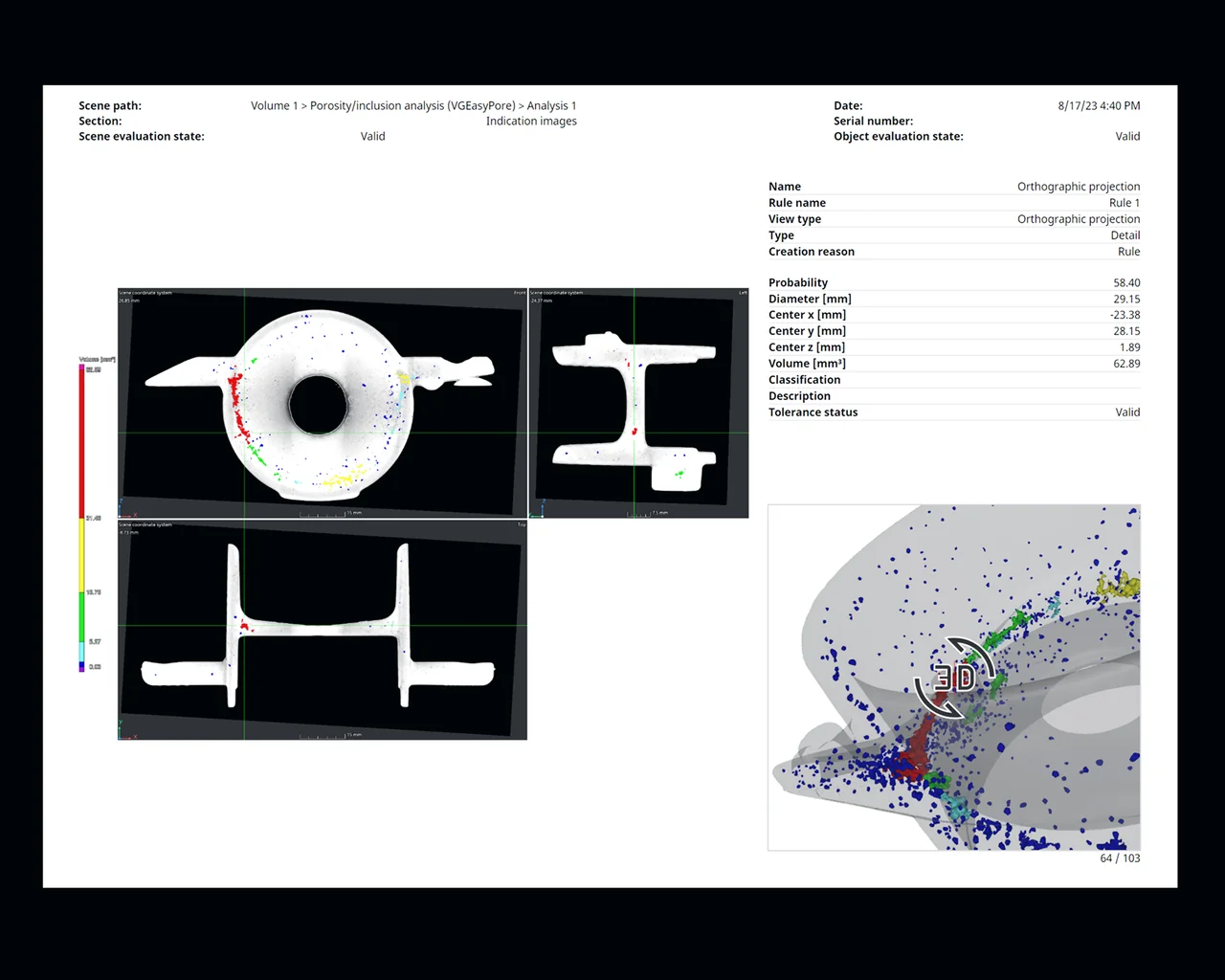

Make Better Quality Decisions with Interactive 3D Images in Reporting

The new interactive indication images in 3D for porosity analyses provide valuable additional context to the 2D indication images, making it much easier to see where exactly in the part an indication is located. This allows you to more accurately gauge the effect the indication might have on the part's quality.

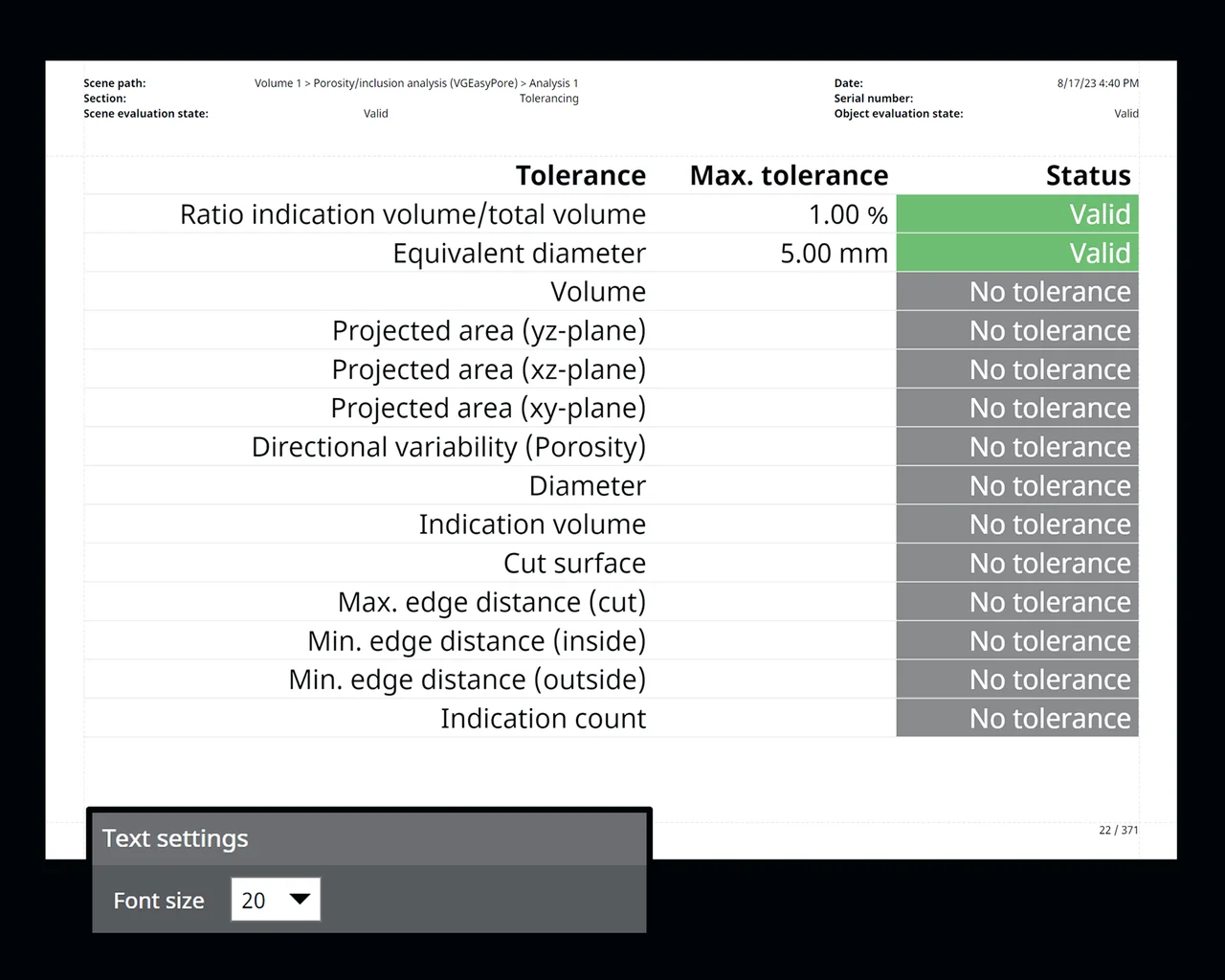

Customizable Report Fonts

You can now adjust the font size for most reporting elements, providing a welcome layer of flexibility when customizing your report layouts and enabling you to easily highlight important information, e.g., part serial numbers or evaluation states.

Easier Interaction with 3D Content in Reports

It’s now easy to see which parts of a report represent interactive 3D content. Gone are the days of any accidental zooming of viewports when scrolling through reports. The improved camera makes it much simpler to focus the 3D views on relevant areas of the reported part.

Customizable Report Images

We now support .svg, .gif, and .jpg images, making it easier to add custom images to reports without needing to convert them first. Custom images also support animations that might be in .svg or .gif files, extending the way reports can be customized.

Usage of Contours as Final Volume Surfaces

The new fixed contours approach (available with the Coordinate Measurement Module) allows you to specify one or several contours (which can be ROIs, meshes, CAD models, or the surfaces of other volumes) and directly convert them into a volume surface. Each contour will be converted to a separate volume component. Should components overlap, subsequently specified components will replace the ones previously created.

Automated Update of Dependent Objects

This new option allows you to automatically update all of an element’s dependent objects when editing it. Simply activate this option in your preferences and enjoy no longer having to manually trigger updates.

Paint & Segment Labeling on Extracted ROIs

Speed up your workflows and train models more quickly by using extracted ROIs rather than the entire volume.

To improve an existing segmentation locally, quickly train and apply a model for a subset of the volume and merge it with the original one.

Create ROI Intersections Directly in Dialog Box

Enjoy a more streamlined process and fewer mouse clicks thanks to the new ability to create ROI intersections directly in the ROI creation dialog box.

Improved Misalignment Correction for CT Reconstruction

In our new semi-automated workflow, you can now easily auto-optimize the determination of the ideal misalignment correction.

Changelog and Bugfixes

General:

- Paint & Segment labeling can now be done on extracted ROIs, which is much faster than on the entire volume

- Added an “Intersect" button to the dialogs for ROI creation

- The scaling function for ROIs, which was lost with the conversion of the “Transform” tool to the “Transform” tab, can now be found on the “Select” tab

- Changed the behavior of the “Transform” tab so that it becomes the active tab when you unlock the selected Scene Tree object

- Added the option to render newly created ROIs to the dialogs for ROI creation. The ROI color can be defined in the “Preferences” dialog

- Added the “Automation” tool to the group of default tools for VGSTUDIO MAX and VGMETROLOGY

- Improved the behavior when deleting a huge number of objects

- Improved the workflow for saving modified volume data of many volume objects

Coordinate Measurement:

- New option for the advanced classic surface determination to create two volume components: one for voids, one for material

- More options for the advanced classic and multi-material surface determination to configure up to which size particles and voids should be filtered out

- New “Fixed contours” approach for the surface determination to use existing contours—for example, from an ROI—directly as the volume surface

- The new rendering of tolerance zones will display the nominal value instead of the actual value. Additionally, the tolerance zone will be color-coded in green (OK) or red (not OK) according to its evaluation state

- New option in the “Preferences” dialog to automatically update all dependent CM objects when editing a geometry element

- The storage system of a geometry element is now displayed in its properties dialog

Analyses:

- Porosity/inclusion analysis and P 203: the new "Voxel-based” gap calculation mode calculates the shortest distance between adjacent indications

- Improved application responsiveness during calculation of porosity/inclusion analyses

CT Reconstruction:

- Added an option that allows you to determine the misalignment correction for CT reconstruction automatically

Automation:

- Improved the "Paste object" macro step so that it is now multi-applicable

Reporting and Traceability (Integrated Report Editor):

- Added the option to upload coordinate measurement, porosity/inclusion analysis, and P 203 results to Metrology Reporting on the Nexus platform

- Added font size settings to all layout elements in the integrated report editor

- Improved the 3D camera controls in the report editor

- Extended the supported custom image formats in the report editor to .jpg, .gif, and .svg

- It is now possible to have individual indications displayed in 3D, along with their rule-based 2D images

- Added visual hints when hovering over 3D elements in the report viewer to indicate which element can be interacted with

- Increased the lengths of some info fields in the default report layout to allow for more content to be displayed

- Added some missing “Data quality analysis (ASTM)” settings to the default report layout

VGinLINE APPROVER:

- Added support for rule-based images for battery anode overhang analysis

Documentation:

- New tutorial "Automating a P 203 Porosity Analysis Workflow"

- New quick start guide “Finding Pores with VGEasyPore“

- New quick start guide “Comparing a Strongly Deformed Part to Its Nominal”

- The following tutorials are now also available in Italian, Spanish, and Russian:

- Rendering a Volume Object

- Segmentation—Based on Geometrical Shapes

- Automation with Macros and Batch Processing

- VGinLINE—First Steps

- Segmentation—Based on Gray Values

- Volume Meshing—First Steps

- Surface Determination for Multi-Material Data Sets

General:

- Fixed an issue where newly opened ROI dialogs would not initially have the focus

- Fixed an issue in the “Manual scaling” dialog where the decimal places where limited to four digits

- Fixed an issue where in rare cases the "Currently active workspace window" option in the "Save images" dialog would not work correctly

- Fixed an issue where in rare cases a debug.log file was created

- Fixed an issue where the “Result as textured mesh” export would fail in some languages

- Fixed an issue where the title bar behavior was not correct under Linux

Coordinate Measurement:

- Fixed an issue with datum systems created from combined planes, where the determination of the material side could be wrong

- Fixed an issue where dragging dimension lines in the 2D views wouldn't update the tolerance values from an active tolerance table as long as the measured value did not change

- Fixed an issue where using adaptive transformation during CM template import could cause lines to flip their orientation and therefore end up with incorrect results

Automation:

- Fixed an issue where the “Log” tab of the “Automation” tool and the “Automation - Advanced” dialog were not in sync

- Fixed an issue where unwanted transformation actions were recorded as a macro step

Reporting and Traceability (Integrated Report Editor):

- Fixed an issue where automatically opening an updated report would not show the correct content

- Fixed an issue where selecting entries in the "Create report" dialog via spacebar would sometimes not work correctly

- Fixed an issue where adding custom images to reports would greatly increase the size of any exported PDFs beyond what would be expected

- Fixed an issue where in rare cases the application could crash if the creation of a report was aborted

VGinLINE APPROVER:

- Fixed an issue where the VGinLINE APPROVER would crash if a log file could not be written

Get It Now

With a valid update/service agreement, you can update your license at no additional charge! Download the latest version of VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, VGinLINE, or myVGL from your Download Account. For more information on how to install and upgrade Volume Graphics software, please refer to this page.

Contact Us—We're Here for You

Don't have a valid update/service agreement? Curious about the new features? Just contact our sales colleagues. They'll provide you with more information and will be glad to assist you in purchasing or evaluating the new version.

Please help us improve our products by reporting bugs and even minor problems or inconveniences. Send an e-mail to our support team or give us a call.

For customers in Europe, Middle East, and Africa:

sales@volumegraphics.com

+49 6221 73920-60

support@volumegraphics.com

+49 6221 73920-80

For customers in the Americas:

sales-us@volumegraphics.com

+1 704 248 7736

support-us@volumegraphics.com

+1 704 248 7736

For customers in Japan:

sales@volumegraphics.jp

+81 52 508 9682

support@volumegraphics.jp

+81 50 5305 1829

For customers in Singapore and other parts of Asia (except China and Japan), Australia, and parts of Oceania:

sales@volumegraphics.sg

+65 6665 0310

support@volumegraphics.sg

+65 6665 0311

For customers in China, including Mainland China, Hong Kong, Macao, and Taiwan:

sales@volumegraphics.cn

+86 10 8532 6305

support@volumegraphics.cn

+86 10 8532 6305